Virtual Reality – Changing How Cars Are Made

The automotive industry has been adopting new ways to work for a while now, since virtual reality and augmented reality started to expand how real-world businesses could function.

There has been a strong adoption of these technologies in many other sectors. In the automotive industry, virtualized realities are becoming key functions in work processes, from mapping out car ideas to the production of finished vehicles.

Showrooms have adopted virtual reality as a sales tool which allows salespeople to show off any car of the brand, without needing to have them in stock at the time. What’s more, virtual reality can also demonstrate the different trim levels and upgrades available across the brand, which is of great assistance to upselling.

Virtual reality and augmented reality are being looked at and developed for use inside vehicles, and this is expected to expand as 5G makes truly autonomous vehicles possible. From heads-up displays for the driver, night vision, or virtual reality activities for passengers, the uses being discovered are expanding. It is expected that in the future, many will be able to enjoy virtual environments and games as they travel, or even work on virtualized devices.

These uses of virtual reality are promoted quite heavily, but one area often overlooked is the research and development stage. Products have been modeled and designed in applications for a long time now, normally presenting 3D models on 2D screens. Now, however, virtual reality is adding a new dynamic to the development process and also opening up the possibility of totally new design concepts for car interiors.

How Can Virtual Reality Assist Design?

Research and design are complicated and expensive processes, especially where cars are concerned. Manufacturers often spend years refining a single-vehicle.

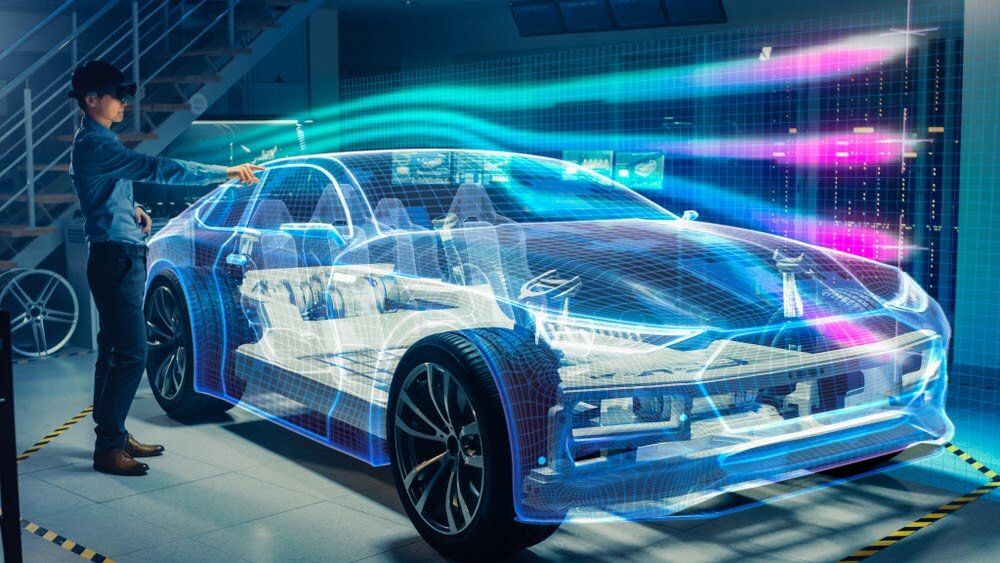

CAD has been a major player in the industry for a long time but is now transitioning towards integrated virtual reality CAD designs. The benefit of virtual reality is that it can provide lifelike, lifesize, and interactive designs.

While modeling on a computer screen is quite effective, being able to see designs to scale, use x-ray vision, and even test them against realistic real-world simulations adds new dynamics to the design process.

The fact that the environment is virtual also helps to increase design collaboration. It doesn’t matter where experts or investors are located, they can join a virtual room to view and collaborate on designs.

With all of the company’s experts and invested parties able to easily be a part of the ongoing development of a design, it allows for continuous progressive development and feedback. This is more favorable to creating “complete” designs and then presenting them only to find that major adjustments are needed. Instead, any element of the vehicle can easily be viewed and reviewed remotely at any stage.

With a virtual model, there is also a more complete feel to the design. Being able to see it to size, move around it, interact with elements and more can help to check the design and functionality better. This can help with everything from aesthetics to finding issues and faults.

The virtual reality environment allows not only for design but also for interactive testing of the designs, allowing designers to see if the things work and if they could be viable. According to seat-mediacenter.com:

“This technology succeeds in reducing production time of the prototypes by 30%”.

Virtual reality has reached the point where a virtual vehicle could be test driven in a virtual world and how it would respond is almost exactly how it would respond when driven in the real world.

This effective reviewing of designs helps to speed up every step, from design through to production, and later virtual reality even helps with online and real-world sales.

How the Use of Virtual Reality could Affect Design Features

We mentioned earlier that virtual reality and augmented or mixed reality could become a big feature of the automobile traveling experience in the future. This, in itself, is likely to affect how cars are designed.

While automation is surely going to change the operation and layout of vehicles, virtual elements could also, in theory, replace current real-world objects. This could, to some degree, even work with manually operated vehicles or remote drivers, allowing for virtual elements to control aspects of the vehicle.

In this sense, we are talking about the possibility of removing a lot of the real-world “interactive parts” from cars, and instead, replacing them with virtual objects. This could either greatly simplify interior designs, swaying more towards space and comfort, or allow for totally different approaches to interior vehicle design.

Elements in the car could also be hidden or interactive by using touch, light, or motion sensors and information systems within the vehicle that interlink with the virtual reality concepts.

How Virtual Reality Could Change Prototypes

Coming up with nice and intuitive designs is one thing, but developing a working prototype is a whole different level. Each development will go through numerous levels of design, discussion, fixes, redesigning, and testing.

If any mistakes are made during this process, the costs can be extremely high. The smallest design fault can lead to halted production or even a total recall of all vehicles sold. This kind of error has further-reaching costs as well, as a brand’s image and consumer trust can be negatively impacted.

Even detecting issues early in the process can cause considerable expense and delays, especially where key components are concerned or being produced for a real-world prototype. This is why it is so important that designers can both effectively design but also collaborate with experts and test design ideas at each step.

Virtual reality is a major asset in every part of this process. It allows developers to visualize the vehicle in a life-sized and interactive environment. Seeing designs at scale can greatly help with detecting issues or flaws that could impact usability, function, or development. Being able to operate or use the designs as they are intended for the real-world only adds more insight to this testing phase.

It also allows experts from any area of the company, or even remote consultants, to collaborate on any part of the design or even the final concept. How parts function or even how an entire engine should perform can be tested. What’s more, numerous situations such as weather, sea level, different surfaces, and more can be simulated to see how things work.

The simplest of mechanisms can be tested, observed, and refined. As the vehicle can be actively interacted with, layout and accessibility issues also become clearer when observed on a functional lifesize model. If issues are found, depending on the advancement of the virtual reality system, it could even be possible to make real-time corrections or switch in already existing alternative designs.

Testing and Driving the Final Version

Whereas before virtual reality any level of real testing required a prototype to be constructed and thoroughly tested, with virtual reality the testing phase can begin before any real-world construction.

Virtual prototyping is now a reality, using a combination of interactive virtual reality and powerful computing to generate realistic and detailed prototypes, as well as ‘real world’ scenarios to place them in.

The days of needing numerous clay models and prototypes are mostly gone. While they may still have some uses, the new virtual models use ‘materials’ that have all the properties of their real-world counterparts. Designers and engineers can check everything from styling to aerodynamics.

Automotive manufactures are already using virtual reality design, as well as using it in other parts of the production process. As stated by thedrive.com “It would no longer be necessary to produce multiple physical models of various items to piece together and potentially reject due to fitment or design conflicts.” This is a huge step, as the research and design stages are both reduced and become more streamlined with the introduction of virtual design and testing.

It also isn’t only the outside or mechanics of the car that can be tested in a virtual space. With advanced virtual environments, it is possible to test what it is like to be in the car and traveling on a journey. This can also be linked to ‘real-world’ effects, such as a mockup of the driver’s area, wind, engine vibrations, etc. Some of these systems allow for live adjustments so that designers can test different styles of items, or even quickly sketch out a new idea from within the simulation.

Many showrooms today are already providing customers with virtual tours of cars, including virtual test drives. While this technology has been around for a while now, new business uses and improvements are constantly being conceived and implemented.

How Virtual Reality is Improving the Production Stage

Staff can now be trained in virtual environments before being set to work in the real world. This allows them to learn, practice, fail, and practice some more in a virtual and safe environment. The training can be created by the design staff and engineers that are specialists in prototype design. Each aspect can also later be adjusted, should any further errors occur. By allowing training from the experts on a particular vehicle design to be used to educate production staff in any area of the company, issues are often avoided.

As an added benefit, the virtual environment doesn’t require resources or machinery, which reduces costs and allows the production line to continue functioning at full speed during training.

Experienced staff members are also not required to undertake training or to take time out to monitor new trainees, helping to increase productivity overall.

When the trainee is eventually ready to start work on the real-world production process, they can still be guided by augmented reality or mixed reality as they work. These headsets can overlay information on the real world, highlight issues, catch malformations, and much more. Even notifications and warnings can be sent remotely to these virtual devices.

To Sum Up

The automotive sector has been quick to adopt virtual technologies. They have been using them for years, and have found intuitive and inventive ways of incorporating virtual worlds into real workflows.

When it comes to prototyping, there are significant advantages to this technology. However, virtual reality has impacted many aspects of automotive production and will likely continue to be adopted further.

To date, some of the impacts of using virtual reality and mixed reality in the automotive industry include:

- Increased safety for trainees and employees

- Increased productivity

- Less downtime

- Reduced costs across various areas

- Improved collaboration without travel

- Faster and more cost-effective prototypes

- Consumer engagement

There are likely many other benefits, but it isn’t hard to see why more and more businesses, particularly in industry, are adopting these virtual approaches to design, testing, training, working, and much more.

Recent Posts

Categories

Luxury Cars

Trucks

Sedans